Universal Boschi is a certified ISO 9001:2000 organization and the latest achievement includes the successful approval for CE certification which makes our company the first in Asia to be certified for Cryogenic Pressure vessel exports to Europe and USA. Among our vast range of Products, the details for the small & medium & “Tonnage series” of plants are given below. Turbo plants due to unique features incorporating low pressure machinery has no capacity limitations or restrictions like Medium & High pressure plants

Note: There is no loss of oxygen Production when producing high purity nitrogen.

Air separation is CRYOGENIC TYPE with low-pressure cycle of 7 Kg/cm2 with air separation by liquifaction. This cycle utilize an Expansion TURBINE to give the cold calories at (-)1 80° C. The cold box is supplied as a complete package unit with control panel and insulation.

This air separation plant mainly includes:

Air enters the self cleaning air suction filter, after being removed of dust and other mechanical contaminants in it, then enters main air compressor, after compression air then enters the after cooler.

Air is cooled in the Pre-Cooling System before enters mole sieve adsorber, Air which enters the evaporator of the Pre-Cooling System is cooled by the refrigerant.

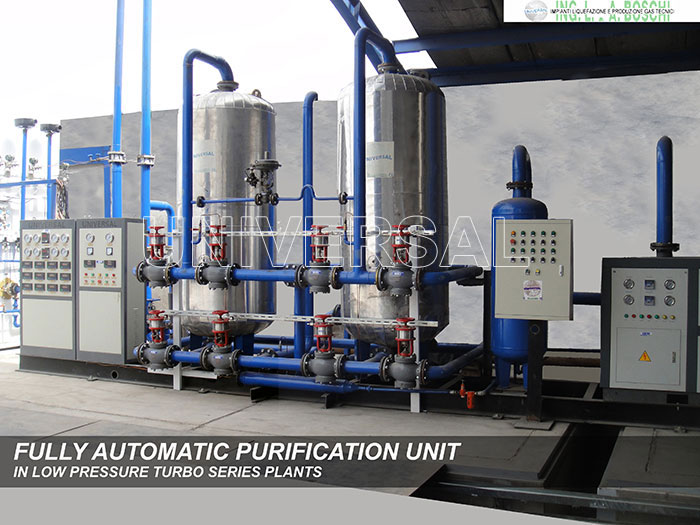

Mole sieve purifying system includes two mole sieve adsorber and Steam heater or Electric heater. The mole sieve adsorber adsorbs water, CO2 and some hydrocarbon in the air, one mole sieve adsorber is regeneration while another one is work.

Air from adsorber is divided two stream: one stream enter directly main heat exchange, then enter lower column after cooled, the second stream enter main heat exchanger to cool after compressed by booster end of the expander and cooled by after cooler, then enter upper column after expanded by the expander.

The content of nitrogen will increase through rising gas connect with the reflux. Needed reflux liquid nitrogen is from condensate evaporator in the top of lower column, oxygen will be evaporated and nitrogen will be condensed in here.

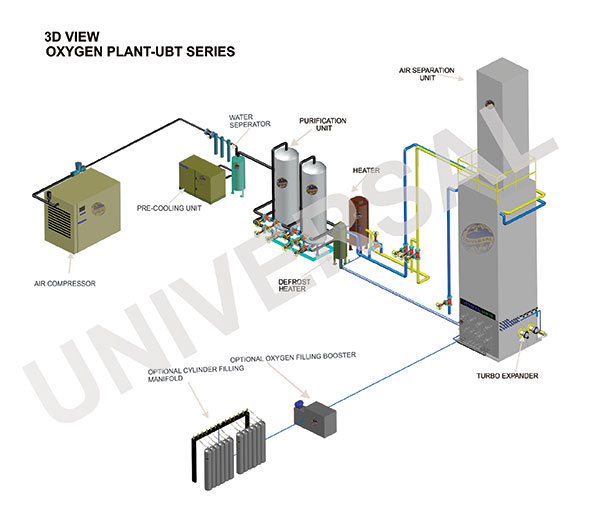

The oxygen plant UBT SERIES consist of the following equipments

The air compressor compresses the atmospheric air through a highly efficient suction filter to a pressure of 30- 40 bar which provides the main raw material for the production of oxygen and nitrogen.

Air Refrigerant compressor including special motor

Molecular Sieve Battery on skid: Complete with 2 nos. vessels, Reactivation heater complete with Molecular Sieve designed for process skid mounting.

Defrost Heater: Consist of heating coils and heating element 5 kW.

Gas/Air Lines as per standard Layout: All pipelines for process air, Nitrogen and Oxygen line, HP line upto manifold along with short bend, elbow, socket and other necessary fitting as per our standard layout drawing.

(Leak proof Cryogenic grade Stainless Column)

Boschi Italy design patent, CE quality and design specifications.

The turbo expander is a rotary machine running on gas bearing. This is used to provide cooling for the liquefication of air at minus 180 to (-)190degrees centigrade. including:

The oxygen is filled into cylinders by an oxygen filling SYSTEM (PUMP/BOOSTER).

Complete with control valves pressure gauge safety valve & pigtail connections points each.

Electrical Panel for supply of electricity to individual motors. With overall suitable size it has a bank of on/off switches MCB/MCCB of high quality Siemens/L&T Make and neatly labeled with separate connections for each individual equipments of the oxygen plant. This enables the Operator to control all the Motors from one point.

Digital Oxygen Purity analyzer Showing Oxygen purity upto 99.9%

|

|

MODEL | CAPACITY IN M3/HOUR | NUMBER OF CYLINDERS PER DAY | Purity of oxygen produced | Pressure of oxygen in cylinders |

|---|---|---|---|---|---|

| OXYGEN NITROGEN PLANTS | UB-25 | 25 | 100 | 99.7% | 150-200 BAR |

| UB-50 | 50 | 200 | 99.7% | 150-200 BAR | |

| UB-80 | 80 | 300 | 99.7% | 150-200 BAR | |

| UB-100 | 100 | 400 | 99.7% | 150-200 BAR | |

| UB-150 | 150 | 600 | 99.7% | 150-200 BAR | |

| UB-200 | 200 | 800 | 99.7% | 150-200 BAR | |

| UB-300 | 300 | 1200 | 99.7% | 150-200 BAR | |

| UB-400 | 400 | 1600 | 99.7% | 150-200 BAR | |

| UB-500 | 500 | 2000 | 99.7% | 150-200 BAR | |

| UB-1000 | 1000 | 4000 | 99.7% | 150-200 BAR |